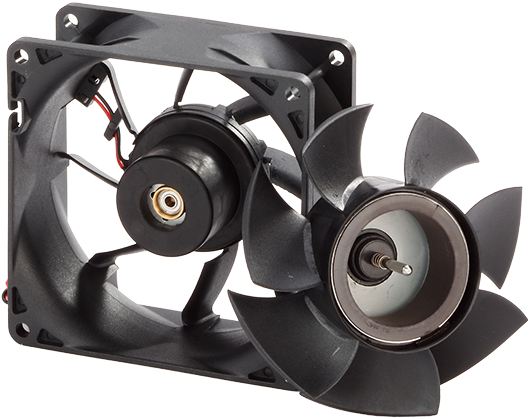

DC environmental fans are engineered to withstand various environmental factors such as dust and moisture exposure. They are often built with weather-resistant coatings and come with different IP (Ingress Protection) ratings, such as IP54 or IP68, to indicate their resistance to dust and moisture. This ensures reliable performance even in harsh environments.

Features

Durable Design: Engineered to withstand challenging conditions while protecting internal components.

Efficient Airflow: Moves large volumes of air for effective ventilation.

Energy Efficiency: Brushless DC motors operate with minimal energy consumption.

Applications

Solar and Renewable Energy Systems: Solar power systems, battery cooling, or small wind turbines, where low power consumption is critical.

Industrial and Outdoor Electronics: Outdoor kiosks, telecommunications equipment, and enclosures that operate in harsh conditions.

Automotive and Marine: Vehicles, RVs, and marine applications for ventilation and cooling in difficult environments.

Air Purification: air circulation, air purifiers and other environmentally controlled spaces.

Mechatronics DC environmental fans are robust, energy-efficient, and versatile, built to handle the unique challenges of harsh and industrial applications. They provide a cost-effective cooling solution in challenging conditions, making them ideal for environments where reliability and resilience are critical.

| Series | Dimensions | Rated Voltage | Input Power | Rated Current | Speed | Air Volume | Max Static Pressure (H2O) | Sound Noise | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | in | V | W | A | RPM | m3/min | CFM | mm/H2O | in/H2O | dBA | |

| G4020 | 40 x 40 x 20 | 1.57 x 1.57 x 0.79 | 5, 12, 24 | 0.6–2.64 | 0.05–0.44 | 4000–8000 | 0.17–0.33 | 6–11.7 | 1.78–5.84 | 0.07–0.23 | 21–32 |

| G5015 | 50 x 50 x 15 | 1.97 x 1.97 x 0.59 | 5, 12, 24 | 0.75–6 | 0.07–0.40 | 2500–6500 | 0.14–0.45 | 5–16 | 1.02–5.59 | 0.04–0.22 | 20–34 |

| G6015 | 60 x 60 x 15 | 2.36 x 2.36 x 0.59 | 5, 12, 24 | 0.45–3.12 | 0.07–0.35 | 2800–5800 | 0.31–0.68 | 11–24 | 2.03–7.37 | 0.08–0.29 | 21–35 |

| F6025 | 60 x 60 x 25 | 2.36 x 2.36 x 0.98 | 12, 24 | 0.624–4.08 | 0.04–0.33 | 2400–5800 | 0.34–0.79 | 12–28 | 2.29–9.40 | 0.09–0.37 | 22–42 |

| MS6038 | 60 x 60 x 38 | 2.36 x 2.36 x 1.50 | 12, 24, 48 | 3.12–16.2 | 0.09–1.35 | 6000–11000 | 0.88–1.64 | 31–58 | 11.94–40.64 | 0.47–1.60 | 39–59 |

| G8015 | 80 x 80 x 15 | 3.15 x 3.15 x 0.59 | 5, 12, 24 | 1–6 | 0.08–0.38 | 2800–4800 | 0.74–1.22 | 26–43 | 2.29–5.84 | 0.09–0.23 | 28–40 |

| G8020 | 80 x 80 x 20 | 3.15 x 3.15 x 0.79 | 5, 12, 24 | 0.84–4.8 | 0.06–0.40 | 2000–4000 | 0.68–1.39 | 24–49 | 1.52–5.08 | 0.06–0.20 | 22–37 |

| F8025 | 80 x 80 x 25 | 3.15 x 3.15 x 0.98 | 12, 24 | 0.9–6.24 | 0.05–0.48 | 2000–4200 | 0.74–1.50 | 26–53 | 1.78–6.60 | 0.07–0.26 | 22–39 |

| MS8025 | 80 x 80 x 25 | 3.15 x 3.15 x 0.99 | 12, 24, 48 | 4.08–9.6 | 0.10–0.72 | 4000–5000 | 1.54–2.00 | 54.4–70.5 | 9.14–13.97 | 0.36–0.55 | 44–50 |

| G8032 | 80 x 80 x 32 | 3.15 x 3.15 x 1.26 | 12, 24 | 1.68–12 | 0.10–0.70 | 2000–5000 | 0.82–1.61 | 29–57 | 3.81–13.26 | 0.15–0.52 | 30–51 |

| MS8038 | 80 x 80 x 38 | 3.15 x 3.15 x 1.50 | 12, 24, 48 | 7.2–39.48 | 0.17–3.29 | 6000–9000 | 2.28–3.42 | 80.6–120.6 | 18.80–39.37 | 0.74–1.55 | 50–62 |

| E9225 | 92 x 92 x 25 | 3.62 x 3.62 x 0.98 | 5, 12, 24, 48 | 1.176–7.2 | 0.06–0.56 | 2000–4000 | 0.82–1.70 | 29–60 | 2.29–8.13 | 0.09–0.32 | 24–43 |

| G9225 | 92 x 92 x 25 | 3.62 x 3.62 x 0.98 | 5, 12, 24 | 1.08–6.96 | 0.06–0.49 | 1200–3200 | 0.68–1.87 | 24–66 | 0.76–4.32 | 0.03–0.17 | 19–34 |

| MS9225 | 92 x 92 x 25 | 3.62 x 3.62 x 0.98 | 12, 24, 48 | 1.2–5.76 | 0.04–0.45 | 2500–4500 | 1.17–2.08 | 41.3–73.6 | 3.05–8.64 | 0.12–0.34 | 33–49 |

| G9232 | 92 x 92 x 32 | 3.62 x 3.62 x 1.24 | 5, 12, 24 | 1.2–8.64 | 0.06–0.68 | 2000–4000 | 0.93–1.93 | 33–68 | 2.54–8.38 | 0.10–0.33 | 23–44 |

| MS9238 | 92 x 92 x 38 | 3.62 x 3.62 x 1.50 | 12, 24, 48 | 3.84–30.84 | 0.08–2.57 | 4000–8000 | 2.29–4.72 | 80.7–166.7 | 10.16–36.83 | 0.40–1.45 | 37–65 |

| MS1225 | 120 x 120 x 25 | 4.72 x 4.72 x 0.98 | 12, 24 | 1.44–7.8 | 0.08–0.65 | 1500–2500 | 1.50–2.27 | 53–80 | 1.78–4.06 | 0.07–0.16 | 26–41 |

| E1225 | 120 x 120 x 25 | 4.72 x 4.72 x 0.98 | 5, 12, 24, 48 | 0.17–8.16 | 0.03–0.60 | 1400–3000 | 1.25–2.63 | 44–93 | 2.29–7.11 | 0.09–0.28 | 28–44 |

| G1225 | 120 x 120 x 25 | 4.72 x 4.72 x 0.98 | 5, 12, 24 | 1.56–9.12 | 0.07–0.72 | 1500–2700 | 1.53–2.80 | 54–99 | 1.78–5.59 | 0.07–0.22 | 26–42 |

| F1238-H | 120 x 120 x 38 | 4.69 x 4.69 x 1.50 | 5, 12, 24, 48 | 2.16–12 | 0.06–0.95 | 2100–3600 | 2.29–3.68 | 81–130 | 4.06–9.40 | 0.16–0.37 | 33–47 |

| G1238 | 120 x 120 x 38 | 4.69 x 4.69 x 1.50 | 12, 24, 48 | 3–15.84 | 0.08–1.20 | 2000–3600 | 2.49–4.47 | 88–158 | 4.32–12.45 | 0.17–0.49 | 34–49 |

| MS1238-H | 120 x 120 x 38 | 4.72 x 4.72 x 1.49 | 12, 24, 48 | 5.76–48 | 0.18–3.45 | 2500–5000 | 3.61–7.67 | 127.4–271 | 5.84–30.23 | 0.23–1.19 | 42–68 |

| G1338 | 127 x 127 x 38 | 5.00 x 5.00 x 1.50 | 12, 24, 48 | 4.2–15.84 | 0.13–1.20 | 2000–3200 | 2.46–3.99 | 87–141 | 6.10–14.99 | 0.24–0.59 | 37–49 |

| MSI1380 | 133 dia x 80 | 5.24 dia x 3.17 | 24, 48 | 120 | 2.50–5.00 | 4500 | 5.01 | 177 | 45.21 | 1.78 | 66 |

| MS1438 | 140 x 140 x 38 | 5.51 x 5.51 x 1.50 | 12, 24, 48 | 1.44–67.2 | 0.06–5.40 | 4500–8200 | 5.05–10.16 | 178.5–358.8 | 29.72–78.74 | 1.17–3.10 | 62–77 |

| MS1751-H | 171 x 153 x 51 | 6.73 x 6.02 x 2.00 | 12, 24, 48 | 12.48–78 | 0.28–6.50 | 3000–5500 | 5.23–11.84 | 184.7–418.2 | 10.67–41.66 | 0.42–1.64 | 56–72 |

| MSI1769 | 175 dia x 69 | 6.89 dia x 2.72 | 24, 48 | 110.4 | 2.30–4.60 | 4000 | 9.77 | 345 | 45.72 | 1.80 | 72 |

| MSI1967 | 190 dia x 67 | 7.48 dia x 2.64 | 24, 48 | 112.8–120 | 2.50–4.70 | 3000 | 10.14 | 358 | 46.48 | 1.83 | 71 |

| TB1656 | 220 x 220 x 56.2 | 8.60 x 8.60 x 2.20 | 12, 24, 48 | 21.6–22.92 | 0.45–1.91 | 2900 | 3.57 | 126 | 52.32 | 2.06 | 67 |

| MSI2577 | 250 dia x 77.3 | 9.84 dia x 3.04 | 24, 48 | 172.8–187.2 | 3.90–7.20 | 2800 | 20.27 | 716 | 85.60 | 3.37 | 76 |

| MSI3116 | 315 dia x 161 | 12.40 dia x 6.34 | 48 | 422.4 | 8.80 | 2100 | 47.43 | 1675 | 80.01 | 3.15 | 76 |

DC Fan Environmental Protection Options

Mechatronics IP rated fans, blowers, and impellers come in a wide range of sizes and shapes. See below for more information about the available DC fan environmental protection options from Mechatronics.

Encapsulation (IP57 – IP68)

Encapsulation is the process of injection molding polyamide material that seals the PCB and motor assembly before installation of the bearings, shaft assembly, and impeller. Encapsulation is designed to prevent water or dust contact with the fan motor windings and PCB assembly.

Parylene Coating (Up to IP56)

Parylene coating is a polymer applied by vapor deposition over the entire surface of the PCB and motor assembly before installation of the bearings and impeller, leaving a thicker uniform protective coating over all electrical components of the fan. Parylene coating is designed for protecting against heavy condensation and some dust, or lightly corrosive atmosphere. The time the PCB and motor assembly is exposed to the vapor deposition process can be extended to increase the thickness and protection levels of parylene coated parts.

Conformal Coating (Up to IP54)

Conformal coating is a polymer applied by dipping the motor assembly before installation of the bearings and impeller, leaving a thin protective coating over all electrical components. Conformal coating protects against light moisture exposure such as condensation, or light contamination by dirt and dust particulate.

Ingress Protection (IP) Levels

What is ingress protection and what is the difference between IP54, IP55, IP57, or IP68 rated fans?

Ingress Protection (IP) ratings are defined by the international standard EN 60529 to identify levels of sealing effectiveness against intrusion from solids or liquids in mechanical or electrical enclosures. The first digit defines the protection level of an enclosure against solids and the second digit defines the protection level against liquids.

| IP_X | Solids Protection Level |

|---|---|

| 0 | — |

| 1 | >50 mm |

| 2 | >12.5 mm |

| 3 | >2.5 mm |

| 4 | >1 mm |

| 5 | Dust protected |

| 6 | Dust tight |

Example:

IP54 = Dust and Splashing Water Protected

| IPX_ | Liquids Protection Level |

|---|---|

| 0 | None |

| 1 | Dripping water |

| 2 | Dripping water when tilted at 15° |

| 3 | Spraying water |

| 4 | Splashing of water |

| 5 | Water jets |

| 6 | Powerful water jets |

| 7 | Immersion, up to 1 m depth |

| 8 | Immersion, 1 m or more depth |